Customized prefabricated steel structure building low cost factory workshop warehouse

Sample project

Steel structure construction has numerous advantages over concrete construction.

1. Steel is a highly durable metal. It can withstand a considerable amount of external pressure.

Hence, steel structures are earthquake resistant whereas concrete structures are brittle. Concrete is not as resistant as steel.

2. Steel structures have a good load carrying capacity unlike concrete structures, which have a low load carrying capacity.

3. Steel is a tensile metal. It has a high strength to weight ratio. Steel structures weigh 60% lesser than concrete.

4. Steel structures can be made without a foundation but this is not applicable to concrete structures as they are heavy.

5. The construction process is faster with steel structures as they are easy to erect. This contributes to faster project completion. On the other hand, concrete construction is time-consuming.

6. Having a good scrap value also makes structural steel a better option than concrete which has practically no scrap value.

7. Steel structures can be easily fabricated and mass produced. They are so versatile that they can be easily assembled, disassembled and replaced. Steel structures can be modified even for last minute changes.

8. Another advantage of steel structures is that they can be constructed off-site by professional steel fabricators and then assembled on site.

9. Steel structures are an eco-friendly option as they are easily recyclable. This means you get to save money in waste management.

10. Lastly, steel structures are easy to transport as they are lightweight. Steel structure construction is a safe option, there are no health hazards of using steel structures in construction.

11. Weifang tailai undertakes all kinds of fabrication projects. Our team of experienced professional steel fabricators is well equipped to fulfill all your fabrication requirements

The main material

Steel frame with Column & Beam

Steel Beam

Steel Column

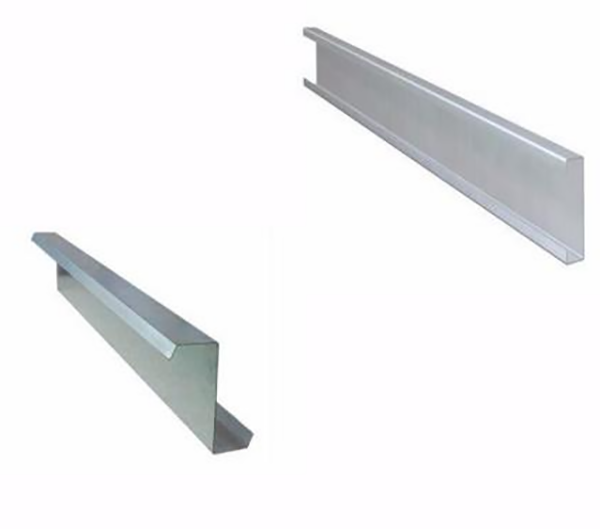

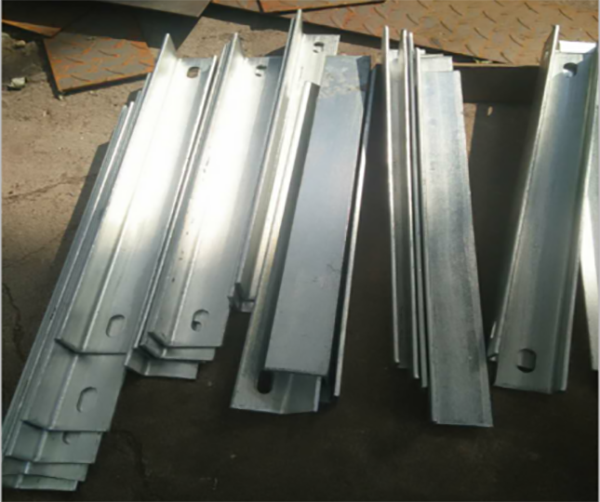

C & Z purlin

Strutting piece

Knee bracing

Tie rod

Casing tube

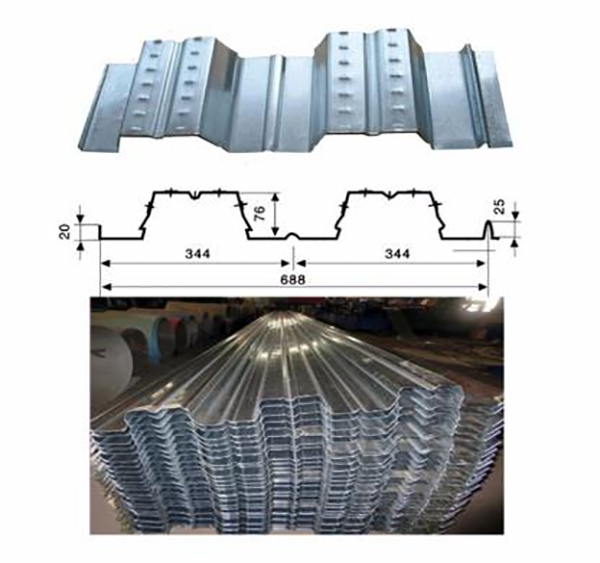

Floor deck

Erection in site

Each piece of the system is very much alike - an H section with end plates for bolting. The painted steel sections are lifted into place by crane, and then bolted together by construction workers who have climbed to the appropriate position. In large buildings, construction can start with two cranes working inwards from both ends; as they come together, one crane is removed and the other finishes the job. Usually, each connection calls for six to twenty bolts to be installed.Bolts are to be tightened to exactly the right amount of torque using a torque Wrench.